Germany, Japan etc 80+ Countries.

Anyang Forging Press Since 1956

China National Forging Hammer Standard Drafter

Anyang Forging Press Since 1956

China National Forging Hammer Standard Drafter

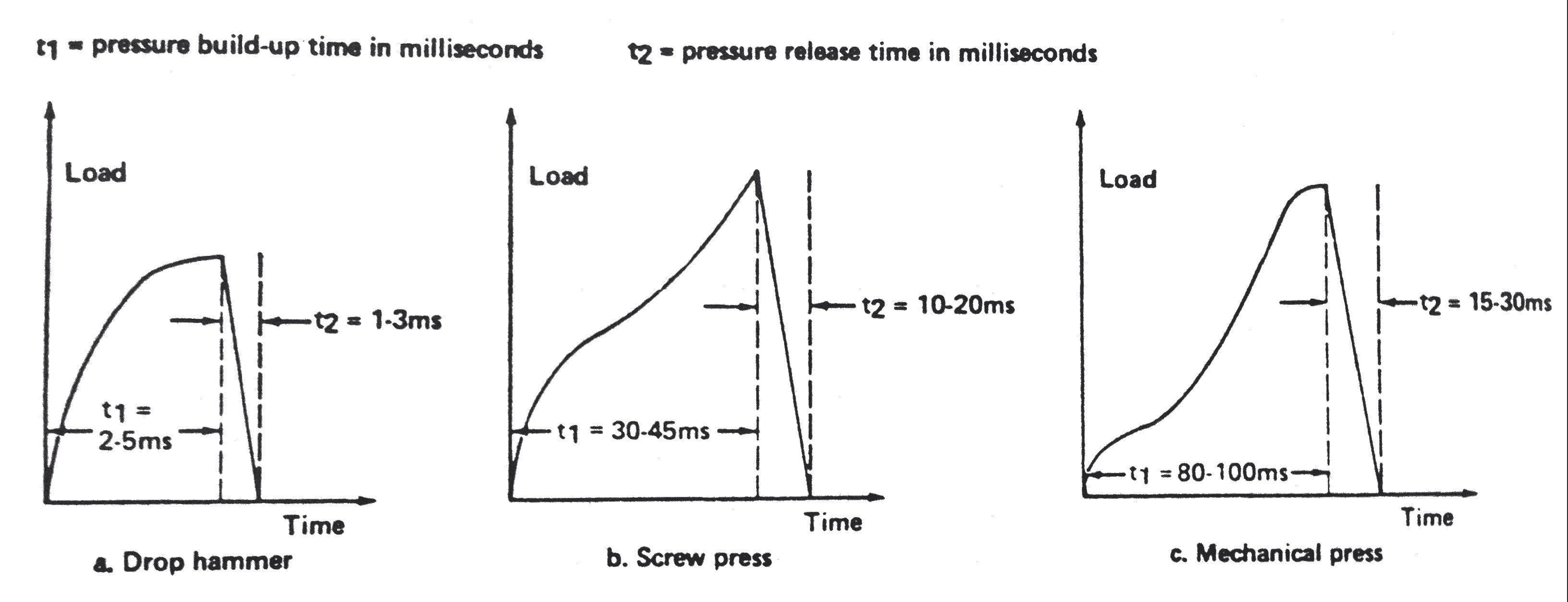

The biggest main difference between the two techniques is the deformation speed (see image below, taken from Powder Forging: Howard A. Kuhn, B. Lynn Ferguson) with all the implications that this has on the formability of the material and on the processing.

Drop hammers reach peak loads in 2-5 ms while press forging, which is usually executed with screw presses or mechanical presses, have maximum peak force between 30 to 100 ms.

Yield strength, being a thermally activated process, changes with strain rate (deformation speed). The image below is for a 20MnMoNi55 steel. As you can see when you increase the speed the material reacts with a higher yield strength and ultimate tensile strength (UTS). Thus with press forging you would need lower forces to accomplish the feat of deforming the piece in the mould whereas hammer forging usually requires multiple hits/blows to fill the moulds.

The remaining differences are a pure consequence:

drop hammers employ operators and are not automatized - the choice of how many blows and with what intensity is based on the operator's experience (with all the advantages and disadvantages that this brings along)

drop hammers are less safe - since the operator requires visual contact barriers are uncommon and hot steel/oxide splinters are always sent dashing thorough the production warehouses (seems odd in 2016 but yes, that's how it still is); in addition given the high speeds when fractures in mould occur it can become a big mess

drop forging is more prone to problems from operators and variabilities in the product

drop forging is very effective in breaking large internal inclusions

modern screw presses are frequently automatized - the stroke is controlled and selected in the set up of the process, the remaining efforts are easy automation and process control

screw presses are more reliable

large parts require huge presses but only large drop hammers - since drop hammers are fast multiple blows are possible so larger parts can be shaped, to obtain the same result with a screw press you need a much larger and complicated system

presses are more versatile than drop hammers - you can use them for closed die forging, open die forging and shaping while drop hammers can be used only for closed die forging

If you want to learn more about forging machine, steel ball machine, briquette press or hydraulic riveter etc products, please send requirements to info@anyanghammer.com