Germany, Japan etc 80+ Countries.

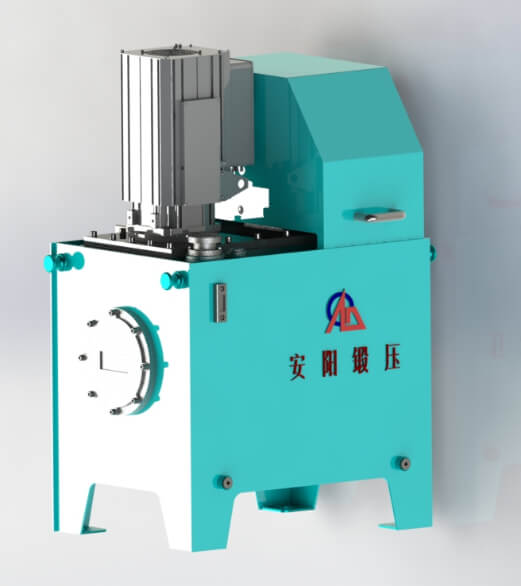

Anyang Forging Press Since 1956

China National Forging Hammer Standard Drafter

Anyang Forging Press Since 1956

China National Forging Hammer Standard Drafter

The riveting machine is a special riveting equipment developed and designed by Anyang Forging Press in the early 1980s to meet the needs of my country's automobile industry and to introduce and absorb foreign technology. With the vigorous development of my country's automobile industry, our automobile riveting machine has undergone several generations of innovation. The hydraulic system of the traditional riveting machine adopts a three-phase asynchronous motor to drive the oil pump to work at a rated speed, and the motor is always at a constant speed. When the equipment is in the state of pressurization and unloading, the motor speed is constant, and the excess hydraulic oil returns to the oil tank through the relief valve, causing energy waste.

Anyang Forging Company has realized energy saving, consumption reduction, green forging, and clean production through the servo transformation and upgrading of traditional riveting machines, and can improve product quality, reduce pollution, reduce costs and improve efficiency for enterprises.

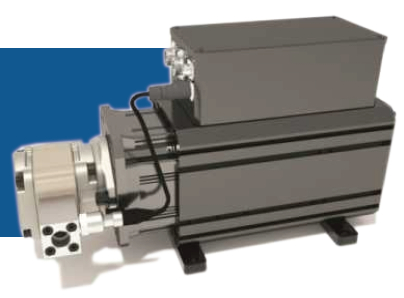

The electro-hydraulic servo system integrates servo technology and hydraulic technology, and adopts the combination of internal gear pump and integrated synchronous servo motor. Intelligently control the speed of the servo motor to achieve the actual pressure and flow required by the equipment.

1. The energy saving effect is obvious, reaching 40-60%.

2. Low noise.

3. The structure is simple, the failure rate is low, the booster cylinder, relief valve, etc. are removed, and the service life of the equipment is prolonged.

4. Energy saving and consumption reduction.

Because the servo riveting machine uses a servo motor, it saves energy, has lower noise than traditional riveting machines, is more environmentally friendly than hydraulic riveting machines, and has high speed, high precision and low maintenance costs. This time, through the servo-based transformation and upgrading of the traditional riveting machine, energy saving and consumption reduction, green forging and clean production are further realized. This is not only a sign of Anyang Forging Press's energy saving and consumption reduction to achieve green forging, but also an important measure to stabilize the global market.

1. No booster system: The direct-drive servo-hydraulic riveting machine developed by our company can realize direct riveting without a booster cylinder. The development of this equipment is to cancel the 1:4 booster system in the existing riveting equipment system. The supercharged cylinder is difficult to process and has a high failure rate. The user's field equipment often has problems such as the system not being supercharged and the equipment maintenance cycle being long. The direct-drive servo-hydraulic system is based on the wide speed characteristics of the synchronous servo motor and has high-speed dynamic response capability. The response time is about 50ms. It has been successfully applied to the hydraulic system. It can intelligently adjust the speed according to the needs of riveting pressure, improve production efficiency and reduce energy consumption. consumption.

2. Servo integrated machine technology: Compared with the same power, the volume of the asynchronous motor is reduced by 30%. Compared with the conventional synchronous servo, the system adopts an integrated solution and the volume is more compact. There is no need to add an additional electric control cabinet to install the driver. space saving. The use of aviation plug wiring eliminates the need for cumbersome wiring operations, plug, and play, and enhances the user's experience.

3. Energy-saving system: The traditional riveting machine hydraulic system adopts a three-phase asynchronous motor, which always drives the quantitative pump to work at the rated speed. When the equipment is in the state of pressurization and unloading, the motor speed is constant, the oil pump always works, and the excess hydraulic oil passes through the overflow. The flow valve returns to the oil tank, resulting in waste of energy consumption and increased oil temperature, and then through the cooling system to reduce the temperature of the hydraulic oil, which makes the structure and principle of the equipment complex and the failure rate is high, especially the energy waste is serious; the direct drive servo-hydraulic system is a fusion of internal gears. The pump is combined with an integrated synchronous servo motor and adopts a double closed-loop control mode. Through the encoder inside the motor and the pressure sensor on the oil circuit, the current flow output and pressure output of the system is tracked in real-time, so as to maximize the efficiency of the system, according to the actual needs of the equipment. The amount of oil is supplied, so there is no overflow loss and energy waste, and the energy saving effect is about 40-60% energy saving according to the frequency of riveting.

4. Low noise and low oil temperature: The noise of the common asynchronous motor is large and continuous. The noise of the servo-hydraulic system changes with the speed change, which is 8-10dB lower than that of the previous year, and the start and stop of the cooling fan can be automatically controlled to operate at a low load of the riveting machine. In this state, the fan does not start to further reduce the noise. The noise of an ordinary riveting machine: is 75 decibels, the noise of a servo-hydraulic riveting machine when pressurized: is 65 decibels and only 45 decibels when fast forwarding and rewinding.

Since the servo-hydraulic riveting machine does not need a high-pressure overflow, and the oil pump is at zero speed when it is not riveting, the oil temperature can be reduced by 10-20°C compared to the traditional ordinary riveting machine.

If you want to learn more about forging machine, steel ball machine, briquette press or hydraulic riveter etc products, please send requirements to info@anyanghammer.com