Germany, Japan etc 80+ Countries.

Anyang Forging Press Since 1956

China National Forging Hammer Standard Drafter

Anyang Forging Press Since 1956

China National Forging Hammer Standard Drafter

Full hydraulic closed die forging hammer

Full hydraulic die forging hammer refers to a die forging hammer whose strike and return stroke of the hammerhead are hydraulically driven. It has the advantages of sufficient energy, fast frequency, no boring mold, low failure rate, and can realize hanging hammer at any position, etc. It is suitable for the production of various types of die forgings.

Working principle of full hydraulic die forging hammer

The full hydraulic die forging hammer is driven by the motor to drive the high-pressure oil pump to provide high-pressure oil to drive the hammer head movement. The equipment is a self-contained system, and the hammer can work when there is electricity.

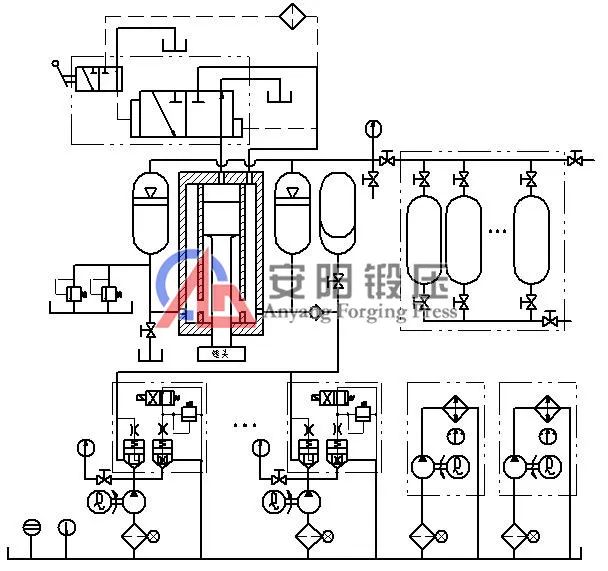

Full hydraulic die forging hammer refers to a hydraulic hammer that is driven by hydraulic oil for the strike and return stroke of the hammerhead, that is, the up and down stroke of the hammer rod. The principle of the system is that the lower chamber of the hammer rod piston is usually connected with high-pressure oil, and the strike and return stroke is realized by controlling the high-pressure and low-pressure conversion of the oil in the upper chamber of the piston.

When the upper chamber of the hammer rod piston is connected to high pressure, the lower chamber of the hammer rod piston is still connected to high-pressure oil, and the connected high-pressure oil acts on the circular area of the upper part of the hammer rod piston and the ring area of the lower part at the same time. Due to the area difference, a downward force is formed. , combined with the weight of the falling part to achieve a downward strike, and at the same time the oil in the lower chamber of the piston returns to the upper piston chamber through the connecting oil circuit; when the upper piston chamber is unloaded to a low pressure, the oil pressure that often acts on the ring area of the lower piston chamber produces The return force overcomes the dead weight of the falling part and the corresponding frictional force to achieve the return.

It can be seen from the system schematic diagram that the main control valve is a hydraulic follow-up valve. When working, the hammer worker controls the five positions of the main control valve spool through the joystick, so as to realize the hammerhead strike, return, slow up, slow down, middle position, and emergency retraction. The operation method is basically the same as that of a traditional hammer.

Full hydraulic die forging hammer features

If you want to learn more about forging machine, steel ball machine, briquette press or hydraulic riveter etc products, please send requirements to info@anyanghammer.com