Germany, Japan etc 80+ Countries.

Anyang Forging Press Since 1956

China National Forging Hammer Standard Drafter

Anyang Forging Press Since 1956

China National Forging Hammer Standard Drafter

With the rapid development of science and technology, competition has become more and more fierce. In order to improve the competitiveness of products, many enterprises are carrying out automatic production transformation of products. Due to the frequent occurrence of mucous membranes during the forging process, production efficiency and product output are affected, and the quality of the forgings cannot be effectively guaranteed. In addition, the die sticking time is too long or the forging rhythm is too fast, which will cause the die temperature to rise rapidly, resulting in die annealing and hardness reduction. , resulting in reduced mold life and increased cost. The traditional manual graphite spraying operation not only has high requirements on the operator, but the atomized graphite milk also causes continuous physical harm to the operator.

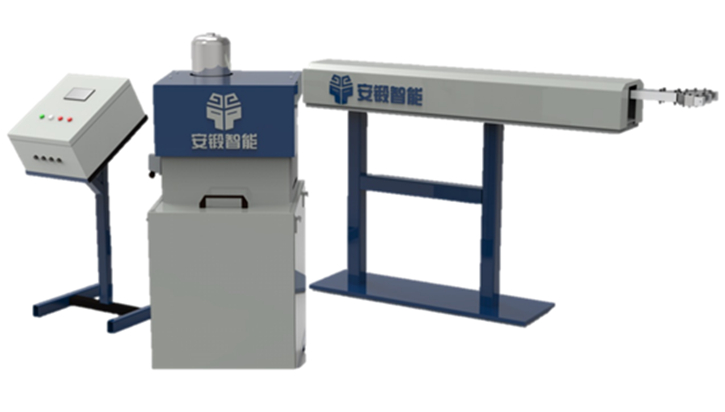

In response to the above problems, Anyang Forging Press Company has upgraded the automatic graphite injection device on the basis of in-depth research on user needs, liberating the labor force of workers, and effectively solving various problems in die forging through the system control of the graphite injection rhythm, achieving efficiency, quality and safety, cost reduction and other data have been comprehensively improved.

Anyang Forging Press Company's automatic graphite spraying device, servo control, precise position, uniform atomization, and graphite saving, not only efficient, economical, safe, and environmentally friendly but also stable and durable, humanized and easy to operate, which can improve the forging cycle and improve the surface of forgings It is a good helper for the production of die forgings.

Four advantages of the automatic graphite spray device of Anyang Forging Press Company

The new generation of automatic graphite spraying devices developed by Anyang Forging Press Company has optimized and improved its functions on the basis of current market products and needs. While meeting the production needs of die forgings, it also solves the existing similar products on the market. The disadvantages in the use process form the four core advantages of the product:

1. Negative pressure extraction is safer: the pressure in the traditional pressure tank structure tank is large, air leakage is prone to occur in places close to the heat source, and even explosions may occur, which poses a greater safety hazard. The automatic graphite spraying device produced by Andu Intelligent adopts the negative pressure of the diaphragm pump to extract and feed the material, which can realize the timely addition of the release agent without stopping the machine;

2. Automatic cleaning and anti-blocking: The mold lubrication and cooling system designed by Andu has a self-cleaning function, which can manually or automatically change the liquid in the system from mold release agent to tap water at the end of each day's work, and then again Carry out the spraying operation (the delay time can be set), flush the pump body and the entire pipeline with tap water to remove the residual graphite milk inside, and keep the pump body and pipeline clean and unobstructed.

3. Fast installation is more convenient: the whole set of equipment has a simple design and structure, and the installation is convenient and fast. There is no need for too many on-site installation and debugging personnel, and the installation guidance can be completed through a video phone.

4. The structure is diverse and more flexible: the spraying method can choose fixed and telescopic mechanisms according to the different mold structures and forging stations, and can flexibly adapt to different forging processes and forging products.

Automatic Graphite Spray Device, why choose Anyang Forging Company?

Anyang Forging Company is an innovative technology enterprise integrating forging equipment design, forging production line transformation, automatic forging production line design and installation, and forging technology consultation. The company integrates research and development, design, service, and adjustment. It has launched a number of fully automatic forging production lines at home and abroad and has provided relevant technical services for the forging production of many customers.

Anyang Forging Co., Ltd. has always been focusing on serving customers around the work policy of technology as the core and innovation as the leading, relying on the in-depth understanding of electric screw presses and forging hammers, the qualifications of our technicians and our management personnel in the forging industry With our experience, we are able to advise our clients on the right solution for every need, including technical and equipment needs.

We can not only provide a brand new complete forging production line but also provide transformation solutions and equipment for the efficiency improvement, automation transformation, energy saving, and emission reduction of customers' existing production lines. We have the expertise to produce forged parts in hundreds of different alloys, covering the entire field of hot and warm forging.

If you want to learn more about forging machine, steel ball machine, briquette press or hydraulic riveter etc products, please send requirements to info@anyanghammer.com