Germany, Japan etc 80+ Countries.

Anyang Forging Press Since 1956

China National Forging Hammer Standard Drafter

Anyang Forging Press Since 1956

China National Forging Hammer Standard Drafter

Steel billets can be processed and fabricated through various forging processes. Among the widely applied metal forging techniques is the closed die forging and open die forging. Although these two types of forging methods belong to the forging basics, it is not so difficult to point out the differences between the two.

Let us have a deeper insight into the differences between open and closed die forging!

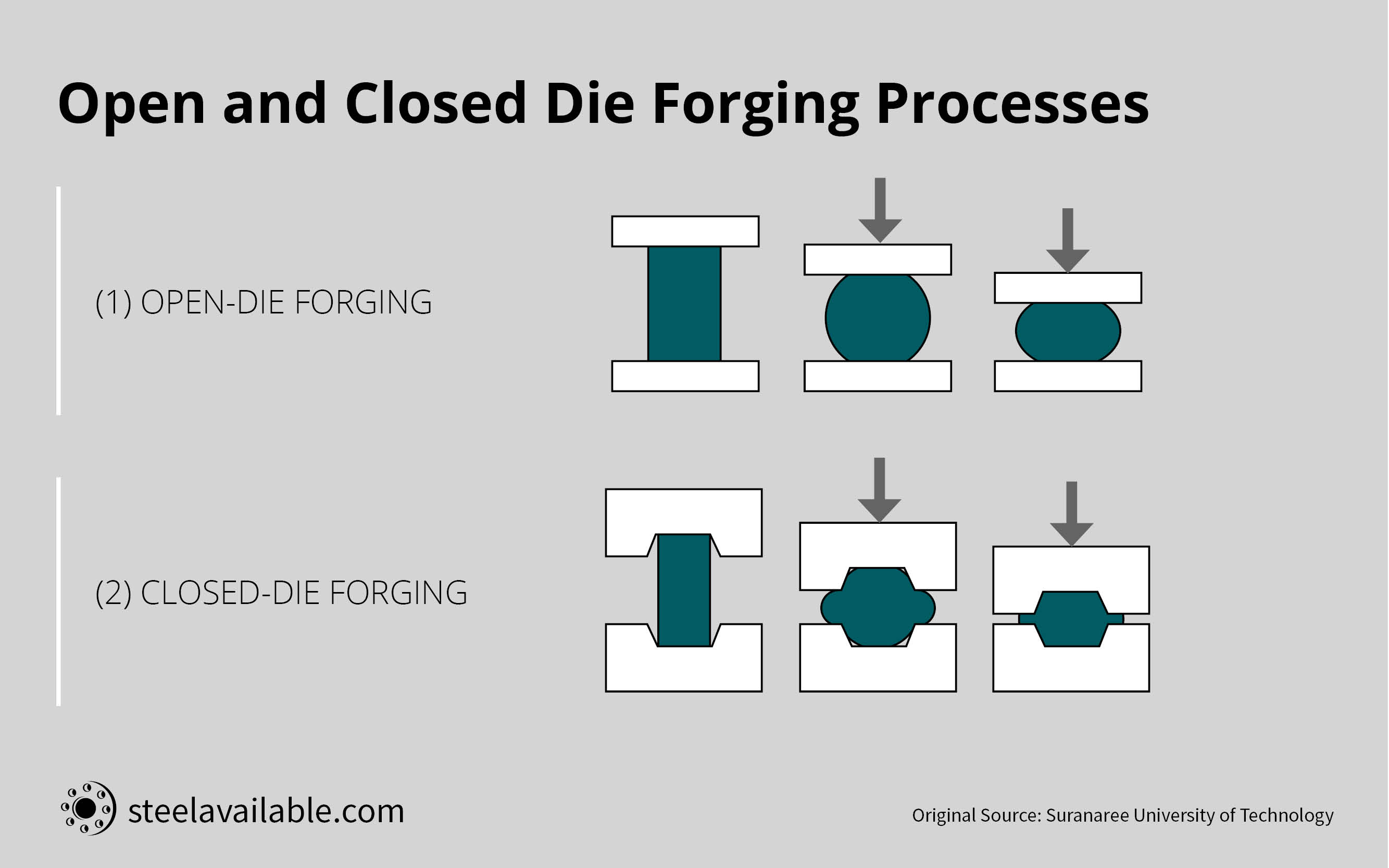

Open and Closed Die Forging Processes in Comparison

Original Source: Suranaree University of Technology

Open die forging process is also known as free forging. The piece of metal is deformed between multiple dies that do not enclose the metal entirely. The dies hammer and stamp the metal through a series of movements to alter its dimensions until the desired shape is achieved.

Closed die forging process is also referred to as impression forging. It utilizes pressure to compress the metal piece to fill an enclosed die impression. A medium frequency induction heating furnace is used to heat the metal to get the desired shapes.

The technique of both open die forging and closed die forging is different. In general, for closed die forging, the molding dies are first made. The metal bars are then placed on the dies and forged to any shapes that are desired. The closed die forging technique utilizes very less or no machining throughout the process. Also, net shape end products can be achieved.

For open die forging, enormous compressive forces are imposed by the continuous strike of a forging hammer to deform the metal billets. Go through the image illustration of the open die forging process here.

Interested in a short visual documentary on the open and closed die forging processes? Check out the forging process video:

The Forging Process of open die and closed die forgings

Source: Youtube

The forged components obtained by open die forging and closed die forging, if compared, are not identical in their application scope. Usually, the metals become stronger and tougher after the forging process due to the modification in its internal grain structure.

A rough precision machining is further required after the open die forging process as imprecise dimensions are achieved by hammering. The open die metal forge parts are more suitable for large parts in a number of tons. Generally, the products in this category of forging include forged long shafts, forged rollers, and forged cylinders. They are mostly utilized in the railway and the aircraft industry.

However, for small parts, closed die forging is preferred as high precision is obtained in the process. It is highly used to produce forged fittings, forged flange, forged automotive parts, etc. Oilfield, automotive, and mining are some of the industries that rely on closed die forge parts.

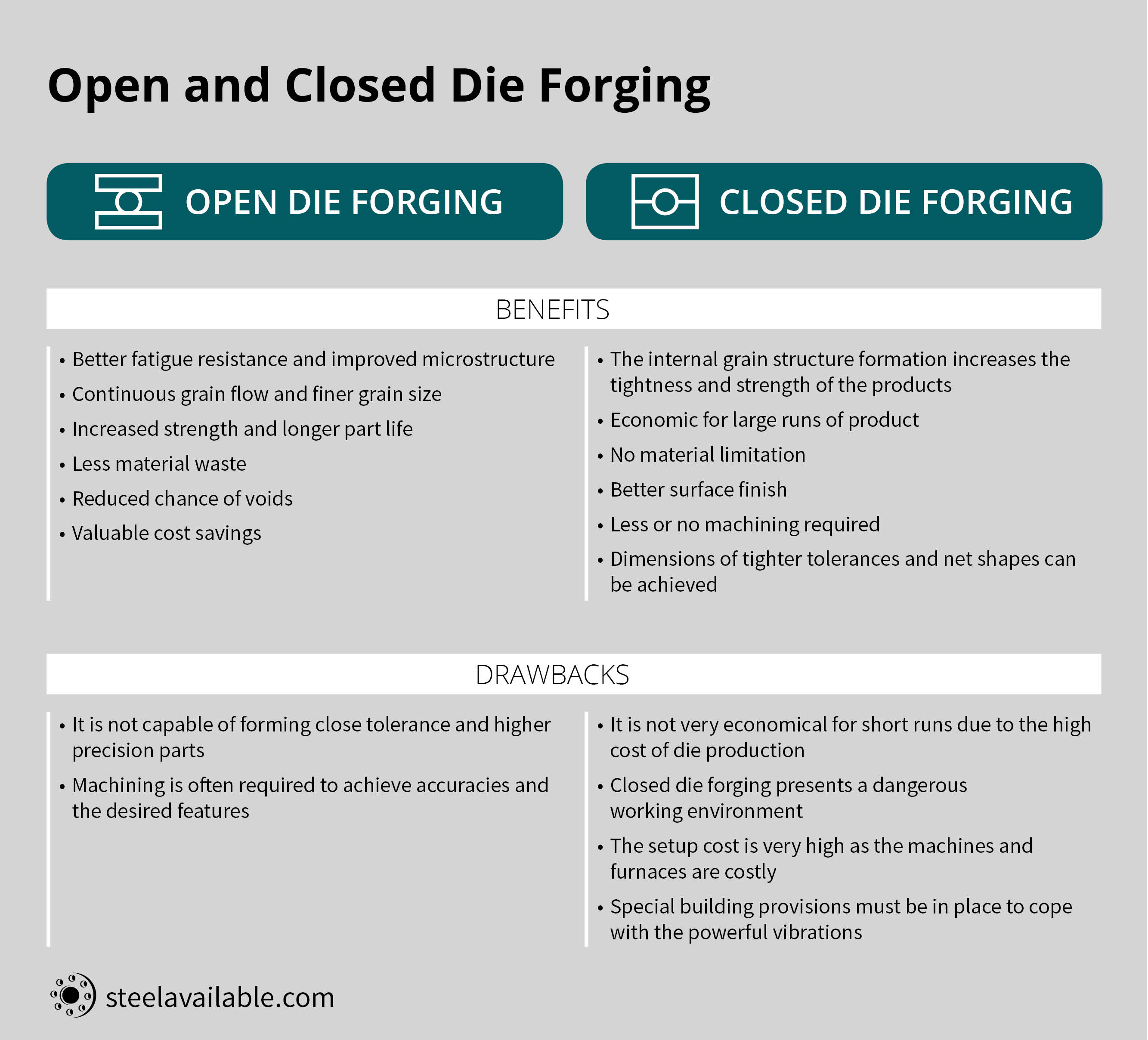

Advantages & Disadvantages

right belong to steelavailable.com

If you want to learn more about forging machine, steel ball machine, briquette press or hydraulic riveter etc products, please send requirements to info@anyanghammer.com